Tips on how to use ventilation systems in your potato storage.

Keeping your potato crop in the best possible condition while in storage isn’t always easy. At a potato storage management workshop in Portage la Prairie, Man. on Dec. 8, 2021, Todd Forbush, vice president and storage systems engineer with Techmark, Inc. gave some tips on storing your spuds.

- Base your storage decisions on your own conditions, not what is happening with your neighbours. While you may get similar weather during the growing season, soils and digging conditions aren’t the same, meaning everyone’s storage situation is unique. Forbush recommends you focus on your storage conditions to make management decisions.

- In a storage ventilation system air is conditioned through a blend of fresh and recirculated air — often through some form of a humidifier. Air is first introduced into the bottom of the pile and then potatoes condition it as it moves through the pile. This introduces “fronts” or layers of potato conditions throughout the pile. Forbush cautions to be wary of too much recirculation.

- A misconception about ventilation is that potatoes are ventilated individually throughout the storage pile. Each potato conditions the air based on if the potato is cold, warm, or humid. Ventilation is only controlling the bottom five to six feet of a potato pile in storage at most.

- Ventilation effects your bottom-line regarding profits. Water leaving a potato costs money as it causes weight loss and pressure bruise. Water left on potatoes causes rot, losing you money.

- Rot can be caused by condensation in potato storage. Condensation occurs when moist air meets a cold surface. Forbush adds condensation can occur within a pile wrecking the quality of the potatoes.

- If temperatures fluctuate when digging up potatoes it can affect storage. Piling cold potatoes onto warm potatoes creates condensation. Forbush recommends avoiding this by cooling the face of the pile to accept cool potatoes the next day.

- You should allow for flexibility when running a fan in potato storage.

- Fans should run at 100 per cent speed when plenum temperature is below pile temperature, or when warming potatoes at harvest, or reconditioning.

- Fan speed should be slowed down during the holding period.

- Potato storage heaters should be placed in the air space above the pile, with circulation fans being used to stir the air. A heater shouldn’t be placed behind a fan in a multiple fan system.

Sugar content tests allow growers to monitor sugar levels in field and in storage to keep potato crops in the best possible condition for shipping to fry and chip processors.

Spud Smart (SS): Why is knowing the sugar content of your potatoes important?

Todd Forbush (TF): We need to know what the potatoes sugar profile is in storage, how they do with bruising, and diseases. A factor that’s becoming more important as we look to transition our processing variety base is determinant versus indeterminant, or what degree of determinants that potato has. We know Russet Burbank is quite an indeterminant potato, as it sets tubers throughout its life as a plant. Whereas some of the newer varieties that are coming out are more determinant, which means they have a single set and that set matures together.

As you might imagine, from a maturity point of view, potatoes that have a single set are much more predictable in terms of their sugar concentrations than potatoes that have multiple sets. Testing these tubers at five, three and one week prior to scheduled vine kill or harvest lets us know the chemical maturity of the crop going into storage. This information is a game changer in terms of storage strategy.

Hal Reed (HR): All of our contracts, at least in Western Canada, are base contracts, which is fine. But it’s your bonuses that are going to make you your money. How is our gravity? How are our colours? These are kind of the things that will give you the bonus. And it’s just too valuable not to keep a handle on those kinds of things.

SS: Why is stress important in regard to sugar tests?

HR: It’s really hard to just say these are my potato fields and treat them all the same. It’s more specific than that. Of course, field selection is super critical as far as slope and the quality of the soil is concerned — is this soil so heavy that it’s going to be a disaster to try to dig it? These kinds of things all come into play. Irrigation is also key. I had one fellow telling me, ‘You know I’m growing potatoes, not fish’ because he was putting so much water on these fields. So again, this is all stuff that you generally already know…

Weather being a wild card is something that’s really hard to manage. Disease control is also vital… So, again, it’s a management thing on how do we give that potato plant the least amount of stress based on control.

TF: To try and get an understanding of how successful this storage might be based on how that growing season — how the variety, the soil, the cultural practices and the weather — how those kind of came together to get us genetic expression of what we know to be this potato. We need to know if that crop is immature, or if it’s over mature? Both have very different needs in storage. And we need to remember that stress compounds these variables that are added into the equation.

Specifically, heavy rains, where we could have some issues where potatoes are underwater for some time, and how that impacts their transitions. Wet potatoes never store well… When it comes to sugars and maturity, drought stress is major. So, if you’ve had issues with irrigation, don’t just write those off and say, ‘Well, that’s over with and done.’ Drought stress or irrigation failure can really cost you some quality. These are all important variables to keep in mind when interpreting potato maturity based on sugar analysis.

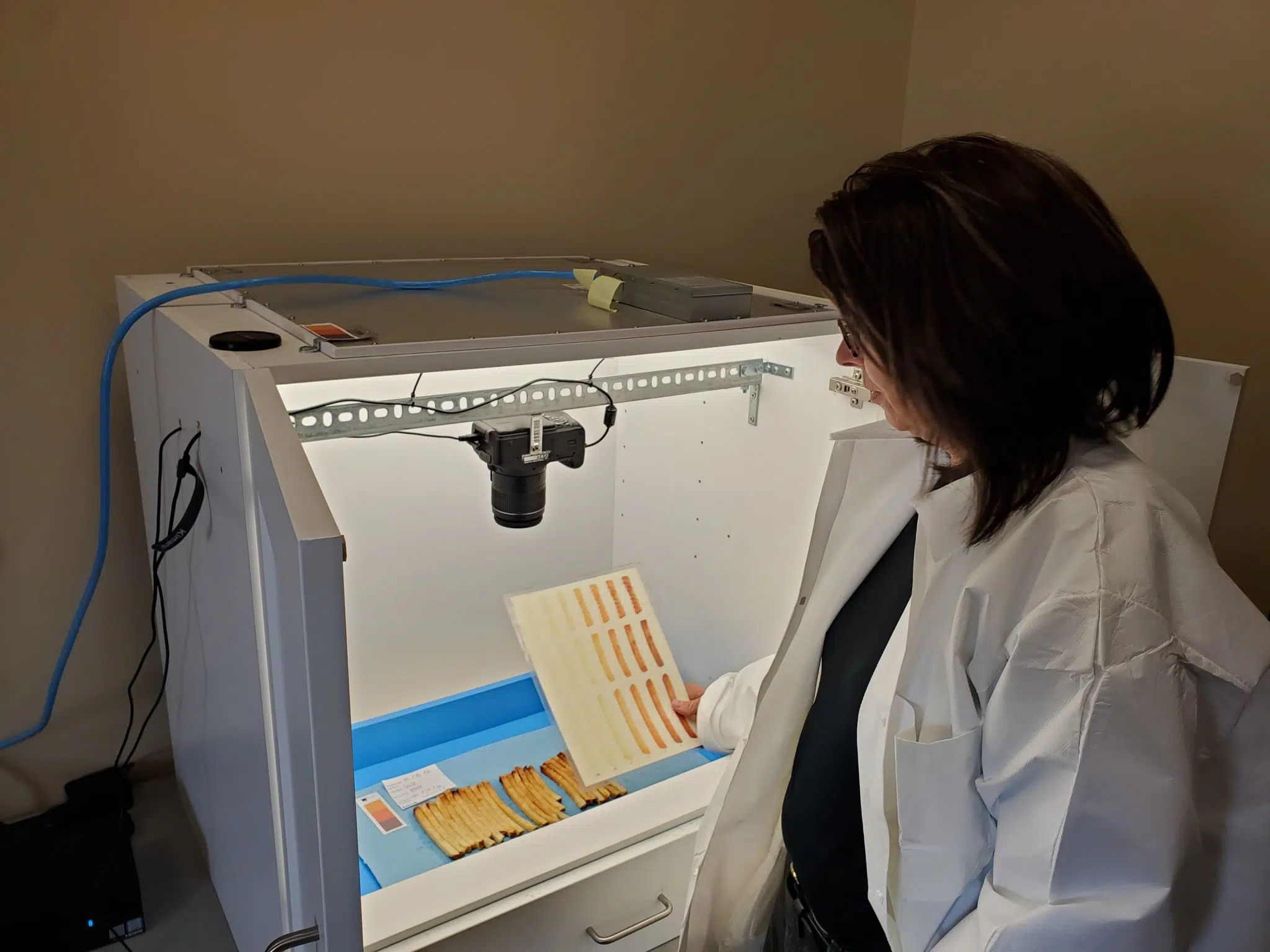

SS: How do you read a sugar report? Sugar test sample example PDF

TF: Along the header you see that these are Russet Burbank potatoes. On the first graph we see sucrose begins at about 2.4 — very high. And over the period of time that we’re looking at here, which is November through January, we can see that the potato sucrose has basically been cut by 50 per cent. The glucose on the other hand has stayed very stable and very high — .5. On this report the potatoes quality was mostly threes and fours on the Munsell color scale.

We can see on the lower graph, no zeros and ones. If this were a report for chipping potatoes the quality data we would look at would be undesirable colour, internal colour, and total defects. So those are the pieces. We’ll break the fries down in zeros and ones, twos and threes and fours. These graphs show regional trends based on variety. The purple line would be the minimum, blue is the average, and green the maximum. We track bin temperature throughout the storage season along with the percent change in quality and sugar data since the previous sample.

SS: How do sugar ratings change with the maturity of plants?

TF: We might not hit what I would call tuber adolescence to get sugars to the point where we need to be to actually store well at our standard practices. So, we need to watch out for what we might call juvenile potatoes. Those are potatoes with sucrose ratings around 2.0. Those do occur sometimes when we have a little later planting, or we have a cool summer where we don’t really get finished off. We then move into the adolescent phase. These are potatoes that can be conditioned, with sucrose ratings from about 1.75 to about 1.25.

These might require some preconditioning, some warmer temperatures early on, depending on the utilization of the crop and when we want to bring it to the factory. Then there are chemically mature potatoes where their sucrose ratings are below 1.25. Now in some of the areas that we’re talking about we’ll have over mature potatoes, where we have a long growing season… We can have a time where we still have real green vines, but we’ve got chemically mature potatoes under those vines.

SS: How does temperature affect sugar ratings?

TF: If we’ve got a lot of sucrose, it’s going to take a lot of respiration to get rid of that because it has to go through invertase to get glucose in and out. And invertase activity is regulated by respiration rate. So, the higher the respiration rate, the higher this conversion, and the higher the supply of glucose is… In the fall, when the outside temperature drops and the soil temperature drops, that potato needs to survive. Its goal is to reproduce. And so, if it gets to the point where it’s starting to get close to freezing in that 28 F to 29 F range, the sugars start to come forward.

And even when you get below 40 F in the soil, we get elevated sugar concentrations. The reason that sugar concentration elevates is to increase the amount of soluble solids in the plant solution — such that will drop its freezing temperature, just like road salt or other things put on the roads helps drop the freezing point of the water so that we can melt the ice — similar case with a potato, it’s trying to survive, so it needs more soluble solids.