With the fifth generation mobile network (5G), a grower can follow the potato from planting to shedding throughout the season. Scouting in the crop and looking for diseased plants can also be done with 5G. Students and the business community are investigating workable solutions, as became apparent during the online seminar of the province of Groningen and LTO Noord about innovations with 5G for agriculture.

Lecturer researcher Jos Bredek from Hanze University of Applied Sciences in Groningen instructed his students to make a smart pager with a chip in it. The pager had to measure the conditions of the potatoes in the back from planting, measure the shocks a potato receives during harvesting and monitor the concentrations of oxygen and carbon dioxide during storage.

All of this should be possible with one battery the size of what is in an average smartphone. Bredek says that the smart beeper must be economical with electricity during the cultivation period. This can be done by transmitting the measurements of moisture and temperature in the soil to the 5G network at sufficiently wide intervals.

During harvesting, the XYZ sensor that measures the movements must remain fully active, a short work peak. The measurements in the storage are again transmitted at intervals. Thanks to 5G, transmission from the ground and from under a mountain of other potatoes is possible. Bredek explains that with tactical choice for the sensors, the method of sending to the network and the type of CPU (the control of the beeper), the battery life can certainly be long enough for an entire growing and storage season. The CPU only wakes up for connecting and transmission and then goes back to sleep to conserve battery.

Ill search

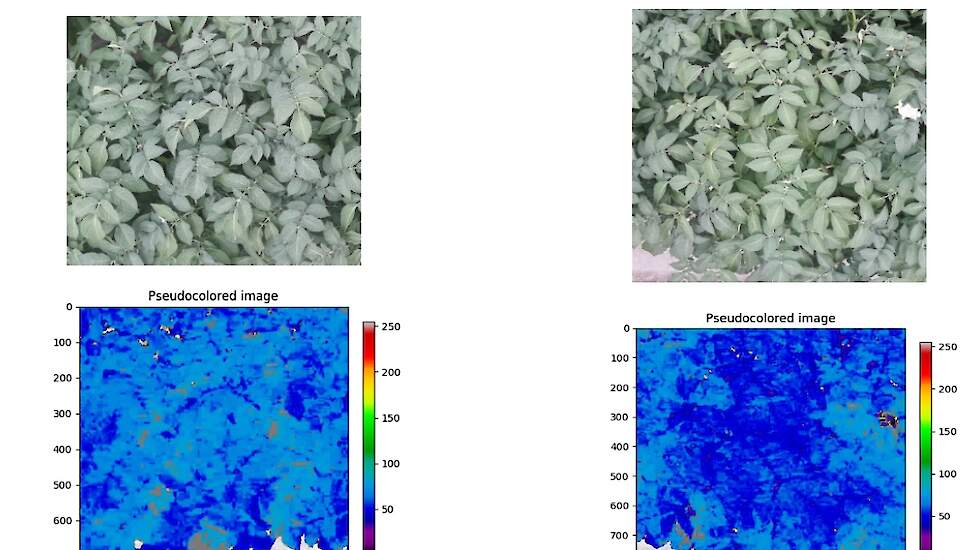

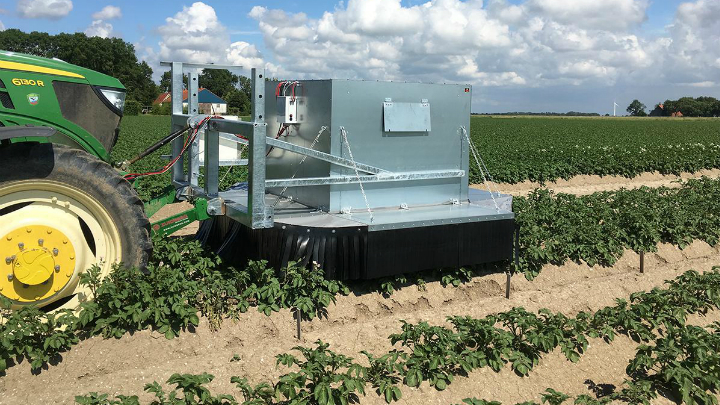

Another application of 5G during (seed) potato cultivation is a robot trolley that detects sick plants in plots. Sietse Damstra, director of the ACS company, explains how this PieperKieker is developed. “We are developing a prototype of this robot. A lot of knowledge of ICT and artificial intelligence is still required to detect potato diseases. ”

The PieperKieker still needs some help in the form of many field images, especially in recognizing clinical pictures well. ACS can develop the electronics and batteries itself. For the data that underlies disease recognition, the company depends on what students and especially farmers can provide.

Damstra has high hopes for the robot. “At Wageningen University they have good experiences with developing this type of technology.” When asked whether it was not possible to make the robot on the basis of other carts or perhaps prefer to use a drone, Damstra replied that the light construction of the robot was especially important, especially due to light batteries. A moving robot, unlike a flying one, can also look at the crop from below.

The trolley makes it easier for the farmer to use and he can work longer at a time than a flying camera. Damstra says that it already has 68 sensors and 6 microcontrollers. He expects that adding sensors that measure substances that diseased plants emit will be a useful extension.