SDI Planning and Design Considerations

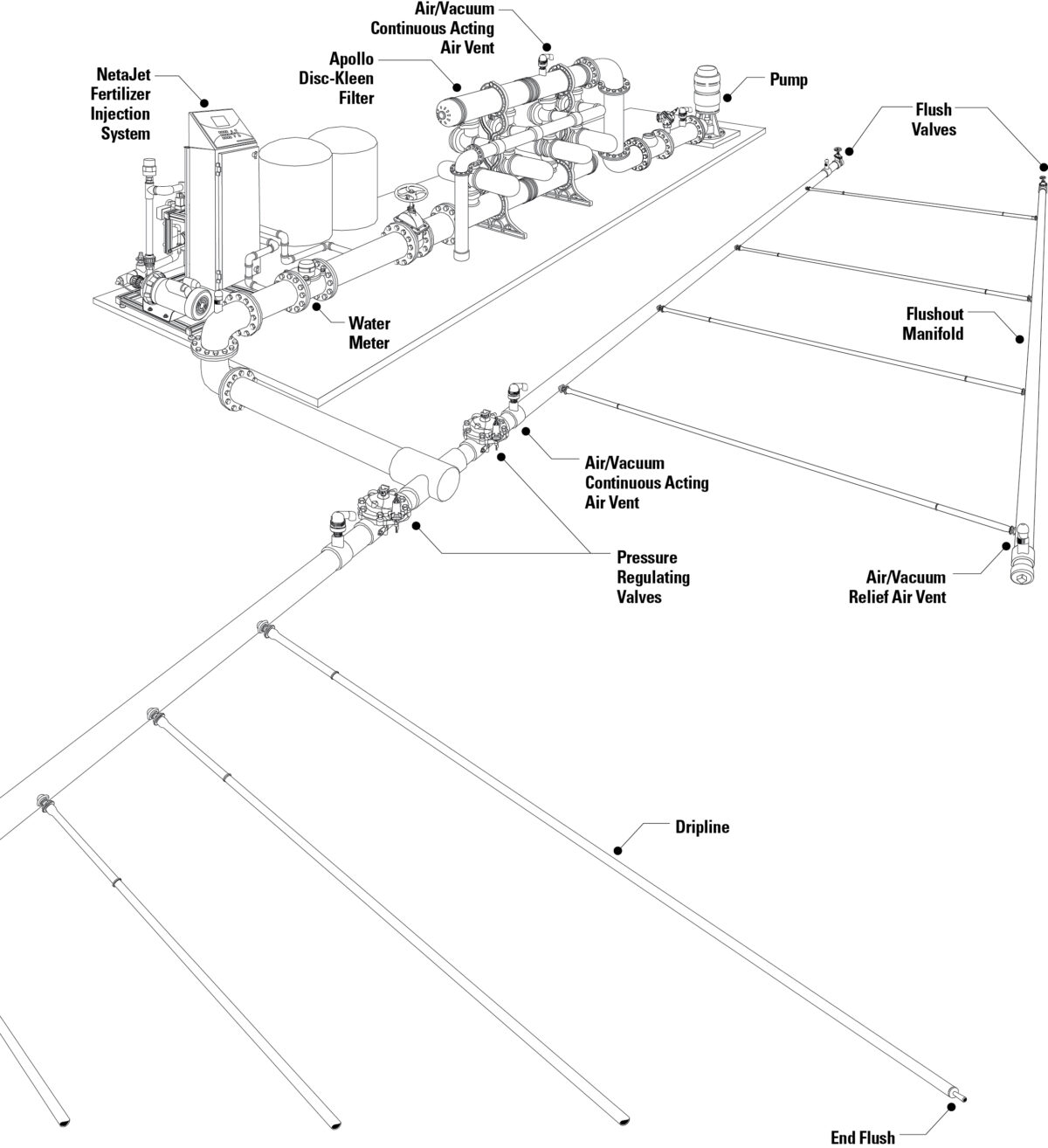

Subsurface drip irrigation (SDI) is one of the most advanced methods of irrigation technology today. SDI gives farmers the ability to apply water and nutrients efficiently where and when they are needed. This results in increased yields and higher quality crops, while saving water, energy, and fertilizer. There are many factors to consider when planning an SDI system; careful attention must be paid to design, installation, and maintenance. A poor design or installation can result in a system that, while possibly functional, will give none of the benefits mentioned above.

Before the system is designed, a well-planned project must first establish the systems’ goals or expectations. These expectations may include increased manageability, better crop quality and uniformity, increased yields, uniform application of water and nutrients, water savings, and increased profits.

Once the expectations of an SDI system are clearly established, conditions such as field shape, topography, soil profiles, and water analysis must be carefully considered to see if those expectations can be realistically achieved.

FIELD SHAPE AND TOPOGRAPHY

The field’s shape and slope will determine which dripper line the designer selects. In general, an undulating or sloped field will require pressure compensating emitters, and a flat field will use non-pressure compensating emitters. The tubing diameter is also critical to supply the flow that the system requires. From a design point, we want to achieve no more than a 7% difference between the highest and lowest emitter flow rate.

SOIL PROFILE

Soil type is also a very important factor in the design. Clay soils allow water to travel much further (upward and laterally) than sandy soils. Clay soils also hold much more water and absorb water much slower. Therefore, drip lines and emitters are generally installed closer together in sandy soils, while in clay soils these spacings can be increased, but with lower emitter flow rates due to the lower absorption rate.

WATER QUALITY AND AVAILABILITY

The most important factor in a successfully operating subsurface drip irrigation system is to properly address any water quality issues. A water analysis needs to be carefully reviewed to understand what level of filtration and treatment is required to prevent the dripline from clogging or calcifying. In most cases, the quality of the water can be easily corrected.

Systems should be designed with the future in mind. They should be flexible enough to allow for unplanned crops and different plant densities to accommodate changes the grower may wish to make.

DRIP LINE LATERALS

Drip line is the heart of an SDI system and is available in many different configurations to meet your unique crop and soil conditions. These configurations include wall thickness, tubing size and dripper spacing, type, and flow rate. Wall thickness is chosen based on the life span of the system, and soil conditions. In undulating terrain pressure compensating emitters are often used, and non-pressure compensating emitters are used if the terrain is flat. The options you choose will determine the overall cost of the system.

Southern Irrigation has strongly recommended Netafim’s DripNet PC drip line for several of our subsurface drip irrigation projects, including our current 625-acre project at Valk Land & Cattle Ltd. Netafim’s integral drippers are injection moulded using state-of-the-art precision machinery. Each dripper includes a precision-moulded filter, making Netafim drippers highly resistant to clogging. DripNet PC is a pressure compensating dripline; the drippers deliver the same flow rate per dripper from 6 psi to 60 psi. It also has the largest dripper inlet filter area on the market and has a built-in anti-siphon mechanism.

FILTRATION

Having the right filtration system is crucial to the performance and longevity of an SDI system. Filtration should be based on the following factors: the water quality throughout the growing season, the dripper flow path, the nature of contamination, and the likelihood of fluctuations in the water quality during any growing season.

Disc filters, such as the Apollo™ Disc-Kleen Automatic Filter from Netafim, offer depth filtration by using a stack of compressed discs that force the debris to move through numerous trap points. The increase of filtration surface area decreases the frequency of cleaning, reducing labour. As debris in the filter accumulates, an automatic backflush process is initiated which releases and flushes out the trapped debris.

In cases where there is a high level of organic particles in the water, Netafim’s Sand Storm™ sand media filters may be used. Water passes through a bed of silica sand, which traps debris. Again, an automatic backflush process is initiated, and accumulated debris is flushed out of the sand.

PUMPS AND INTAKE STRUCTURES

There are many different pumps that can be used to supply water to the system. The most common pumps are centrifugal pumps or vertical turbine pumps. Centrifugal pumps are surface mounted and use suction to bring the water from its source into the pump. Vertical turbine motors are mounted directly over the water source and have a pipe and series of impellers in the water directly beneath it. Vertical turbine pumps, though generally more expensive than a centrifugal pump, offer less maintenance and are simpler to operate.

An intake structure is usually required when drawing water from a creek, canal, or stream. Sufficient water must be diverted to the intake of the pump system, and a coarse screen should be installed to prevent fish, logs, and other large debris from entering the system.

WATER METERS

It is good practice to monitor the system’s operation flow and the crops’ water use. An SDI system is designed to produce a specific flow rate at a given pressure. Changes in the flow rate may indicate leaks in the system, plugged emitters, improperly set pressure regulating valves, or even changes in the water source and pumping station.

FERTILIZER INJECTION

Fertilizer injection systems inject nutrients and chemicals into the system for maximum crop performance and to maintain the dripline over a long period of time. Flexible fertigation capabilities will help the system pay for itself faster than any other component in the system. Growers often neglect to use this feature to its full potential due to its perceived complexity (uncertain over what to inject), or simply not knowing how valuable it is. Injection systems should meet expected demands for all chemicals, be easy to operate and calibrate and have provisions to prevent unwanted precipitates.

Maintenance

Winterizing the system is a necessary maintenance procedure as water will freeze and expand, possibly damaging plastic and metal system components. Water from filters, valves, chemigation equipment, pressure regulators, and subsurface pipes should be emptied – especially at lower ends of the field where water typically accumulates. Polyethylene drip lines are not subject to damage from freezing since the drippers provide drainage points and polyethylene is flexible.

Routine maintenance of all system parts (such as filters, pumps, valves and fertilizer injectors) will extend the life of the system. Maintenance should follow a regular schedule and should be recorded for later reference.

Is SDI Right for You?

SDI is not the answer for every grower, or every crop, or every climate. There are many variables that need to be considered carefully. That is why it is so important to have a clear goal in mind before choosing to install an SDI system. Speak to our team of qualified designers and agronomists to see if these goals can be reasonably achieved. We want successful systems with very clear and measurable returns on your investment!

southernirrigation.com DRIP IRRIGATION SYSTEM irrigation-equipment