FULLY AUTOMATIC IRRIGATION IS A REALITY.

A 25-year veteran in the irrigation industry, Ken Goodall is astounded by recent advances in irrigation automation. “It’s coming like a freight train,” he predicts. “In the coming years, farmer adoption of pivots that run themselves will skyrocket. And we are talking more than pivots turning themselves on and off or adjusting operating speed. Pivots are being equipped to automatically vary their applications

rates to current field moisture conditions based on soil sensors, aerial imagery, weather data, crop modeling, and user input.”

Welcome to the first autonomous machine in agriculture, the center pivot.

Goodall works for Reinke Manufacturing, who along with Valley Irrigation and Lindsay Corporation are introducing autonomous advances at a rapid pace. For example, Reinke just secured a partnership with CropX, whose technology offers site-specific irrigation recommendations on a variety of factors including CropX maps, aerial imagery, weather, modeling, user input, and a patented soil sensor. Earlier this year, CropX acquired CropMetrics. That acquisition added more than 500,000 acres of soil data to the CropX farm management platform.

ARTIFICIAL INTELLIGENCE

In the meantime, Valley has expanded its partnership with Prospera Technologies, an Israeli machine vision and artificial intelligence company. The collaboration, known as Valley Insights, employs artificial intelligence and machine learning to transform a pivot into an autonomous crop-management tool. “Valley Insights is designed to move growers closer to autonomous crop management,” says Troy Long of Valley.

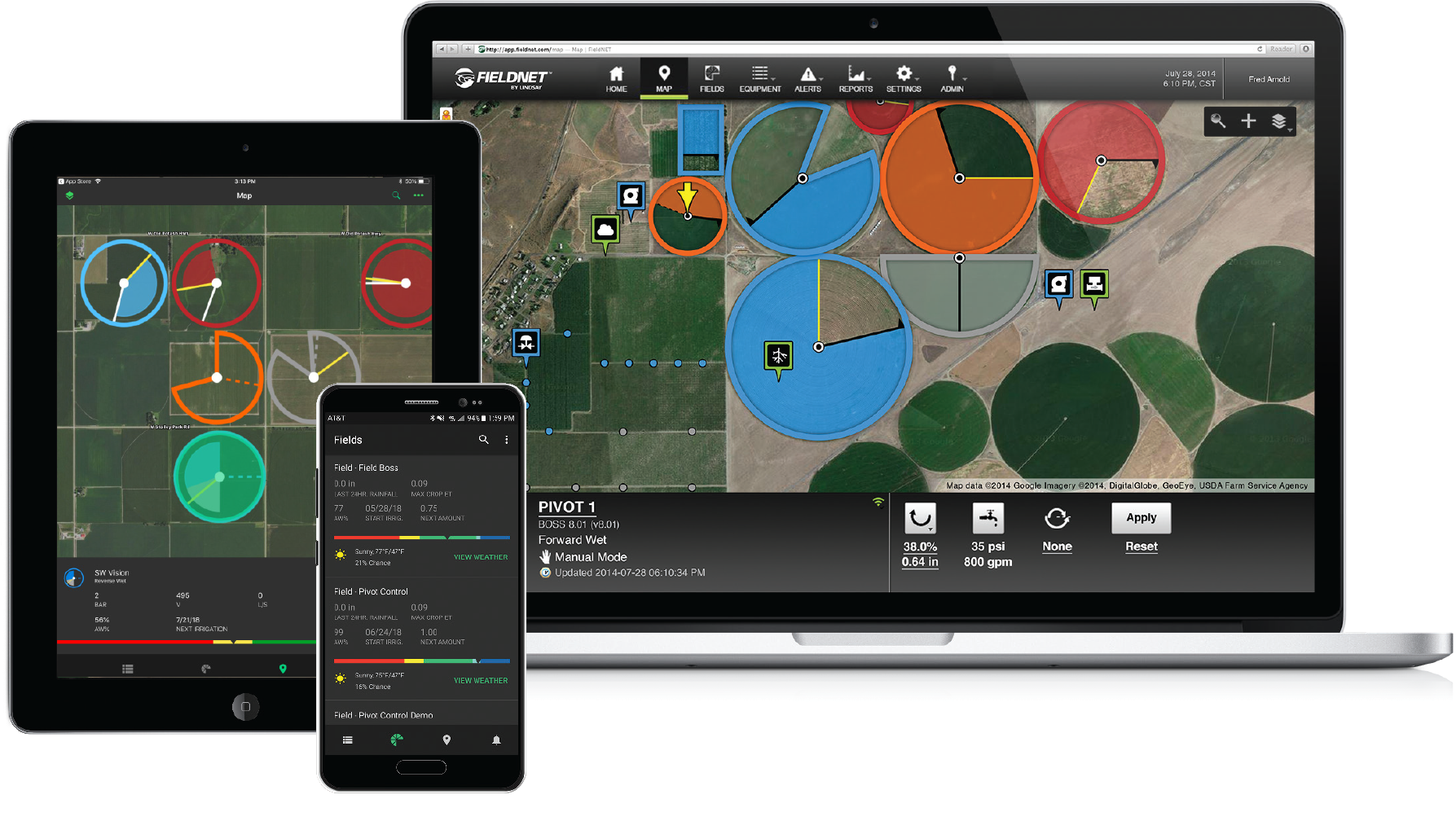

Lindsay has expanded the capacity of its FieldNET remote monitoring and control technology; this extends its ability to vary application rates. FieldNET capabilities include the Advisor program, which analyzes data to provide daily application recommendations.

VRI ADOPTIONS

Farmers are already capitalizing on various forms of pivot automation. For example, Wes Boorman employs Lindsay’s FieldNET with that company’s Precision VRI (variable-rate irrigation) solution to expand existing pivots’ ability to “apply different rates to different areas of a field, which helps us increase yields,” says the Moses Lake, Washington, farmer, who added VRI technology to his cornering equipment. “Our yield maps look like our topography maps. The higher ground yields less, and the lower ground yields more. To increase yields, we had to find a way to add water to the higher ground without overwatering the lower ground. VRI provides the ability to do that.”

This technology lets growers customize water or chemical rates for each area of the field. Nodes control each individual sprinkler on a pivot turning them on, off, or pulsating their water application. This is done according to field position and desired application depth. “With Wes’s corner, we’re able to maintain 100% of the flow while traveling around the field,” explains Aaron Sauser of Lindsay Corporation. “To do this, we change the pulse rate and travel speed at the same time. As the corner is fully extended, the machine runs slower and we apply fewer sprinklers on the mother machine, sending the flow to the corner. As the corner closes down, we speed up the machine’s travel speed and turn more sprinklers on in the mother, or parent, machine. In doing this, we apply the same rate of water to all acres. This also reduces rotation time.”

SCHEDULING APPLICATIONS

Precision scheduling of application is also drawing a lot of attention from farmers due to advances

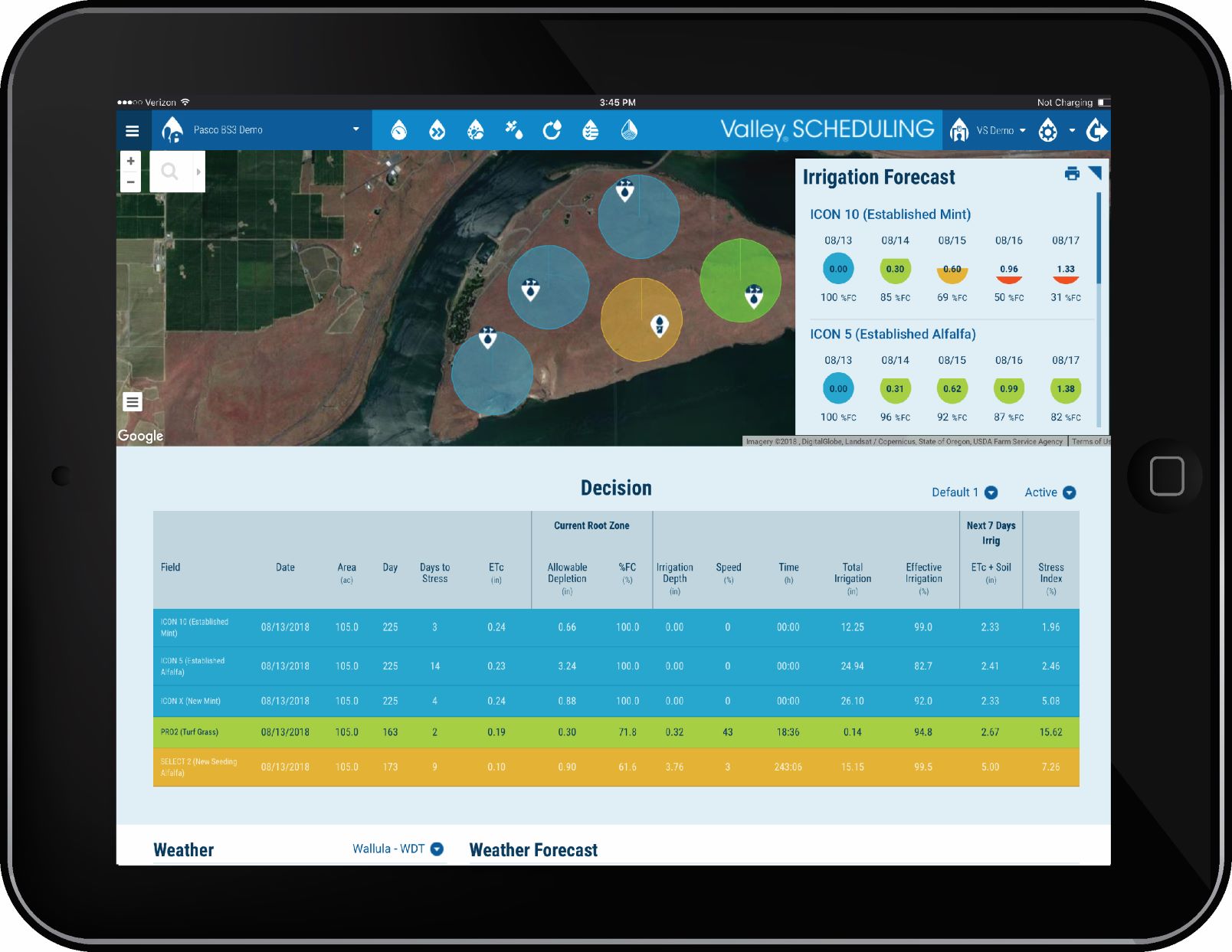

that not only generate recommendations based on up-to-date field conditions but also provide the ability to schedule watering remotely. Greg Juul, co-owner of G2 Farming near Hermiston, Oregon, uses the Valley Scheduling technology, which “gives us the opportunity to have everything at a finger click,” Juul says. “It’s almost another set of eyes in the field, in terms of where your soil moisture is, especially with critical crops.”

Valley Scheduling, coupled with the services of an agronomy expert, provides watering recommendations based on farm information, preferences, and field data such as soil, crop type, development stage, and weather information source. The software compiles the data and shows how much water is needed in an intuitive map or list view.

Reinke’s advances in this area, SAC (swing arm corner) VRI, are now available on most pivot models equipped with that company’s AnnexPF for RPM Preferred panel. The software permits zone VRI by dividing coverage areas into multiple concentric rings. The result is a pivot with more than 300,000 application zones.

“We have one farm that gets its water from a deep well, so we’re using SAC VRI in an attempt to only put on the amount of water needed on the areas that need it the most,” explains Mark Gross of the Spokane Hutterian Brethren Farm of Reardon, Washington. That farm installed the Reinke Advanced last spring. “SAC VRI allows us to extend variable-rate capability to the rest of the field. We already have 13 machines with VRI on the pivot itself, so we’ll most likely add corner-system VRI to more of them.”

EXTENDING TO CHEMIGATION

Varying rates to field condition has also extended into chemigation. Agri-Inject, for example, recently introduced technology that puts fluid injection at an operator’s fingertips via smartphone, tablet, or computer. That company’s ReflexConnect offers programmable variable-rate application of fertilizers and chemicals. “Producers can start, stop, or monitor fluid injection with their cell phones or tablets,” says Erik Tribelhorn of Agri-Inject. “They can also use the web interface to change the chemical injection rate in gallons per acre or gallons per hour, depending on the mode – or even change modes.”

In addition, with ReflexConnect, a farmer can set and adjust alarms including set points, system shutdown values, and notification targets. The technology’s dashboard features access to reports, charts, logs, and downloadable files. Localized weather conditions including temperature, rainfall, and wind speed are also available.

ReflexConnect users can configure up to five application settings and store each with a unique name, enabling quick selection of complete configurations at a later date.